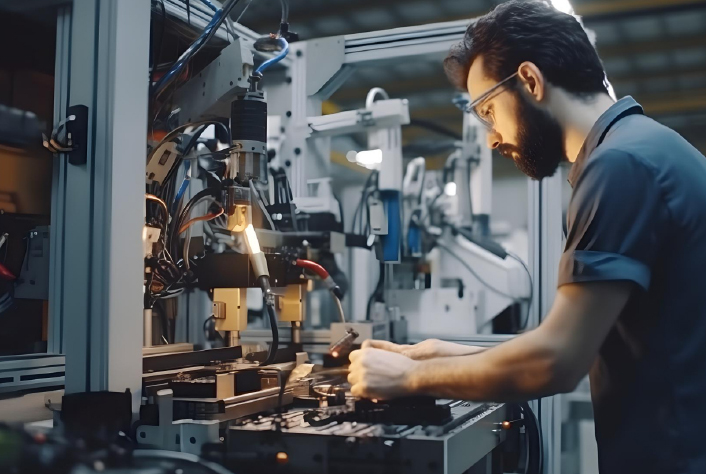

Discover our advanced manufacturing facilities dedicated to rubber molded products. With state-of-the-art technology and meticulous attention to detail, we ensure top-tier quality and efficiency throughout the production process. From design to delivery, our expertise guarantees results that meet and exceed industry standards. Experience the pinnacle of manufacturing excellence with our innovative solutions and commitment to quality.

Infrastructure

State Of the Art Manufacturing for Rubber Moulded Products

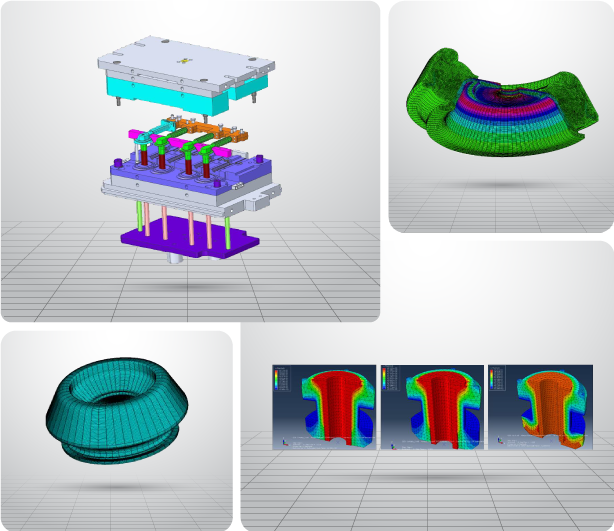

Research & Development

Rubber & compounding capabilities

- Exclusive prototype facility

- Over 500 different rubber recipes in library

- Quick access of existing recipes by keying-in basic rubber properties

- On-line data integration with mixing unit

- Separate small-scale kneader to reflect production mixing conditions

- Reverse engineering capabilities

Design capabilities

- 20+ Engineers and 10+ rubber technologists

- CAD/CAM interfacing

- Shared CAE facilities for Non-linear analysis

- Wide usage of TGR/TGW approach

- We use ABAQUS, SIEMENS NX and AUTOCAD software for designing

Manufacturing Facility

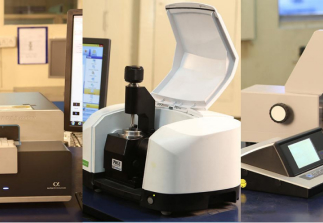

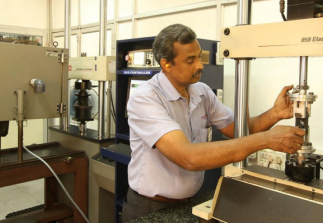

Lab & Product Testing Facility

Product testing facilities

- 50 Tons bi-axial testing equipment

- 1 Ton static & 100 HZ dynamic testing equipment with environmental chamber

- 2 Tons static & 100 Hz dynamic testing equipment

- 10 Tons uni-axial endurance testing equipment with environmental chamber

- 5 Tons bi-axial testing equipment

- Radial test, Torsinol test, Axial test, Cardanic / conical test

State-of-the art laboratory housing

- Micro hardness tester

- Dispersion analyser

- Thermo gravimetric analyser (TGA)

- Differential Scanning Calorimeter

- FTIR Spectroscopy

- Zwick UTM

- Ozone chamber

- Low temperature cabinet

- Demattia flex testing

- Din abrasion tester

- Oscillating rheometer

- Moving die rheometer

- Specific gravity meter