Our History

A Single Man's Dream to a Business Conglomerate

T V Sundaram Iyengar started his entrepreneurial journey in 1911. He wanted to build a business that would create a family of like-minded individuals pursuing only the best in quality and standards. The success of the company is deeply rooted in our founder’s personal belief of commitment to the values of trust and customer service. Although the company was named after the founder, the letters TVS have always stood for Trust, Value, and Service within the company. It was only natural that success and market leadership followed.

About TVS Mobility Group

TVS Mobility is the holding company for businesses managed by the T S Rajam family members. The companies housed under TVS Mobility evolved from the business started by T V Sundaram Iyengar in 1911. The group has a diverse business base in both B2B and B2C, with clientele that includes marquee names in both the auto and non-auto segments. The companies have grown consistently over the years and are focused on expanding their reach and moving to newer markets, while maintaining excellence and building sustainable business practices. Learn More

Business Segments

Our Business

Why should you prefer us

Unlocking Excellence:

TVS's Century-Long Legacy of Trust and Innovation

From Design to Delivery:

Our End-to-End Solutions Guarantee Precision and Quality.

Time is of the Essence:

Prioritizing Swift Delivery and Reliability in Supply Chain Management.

Global Reach, Local Excellence:

Our Networked Supply Chain Delivers Anywhere, Anytime.

Your Growth, Our Commitment:

Beyond Specifications, We're Partners in Progress, Fostering Innovation and Development.

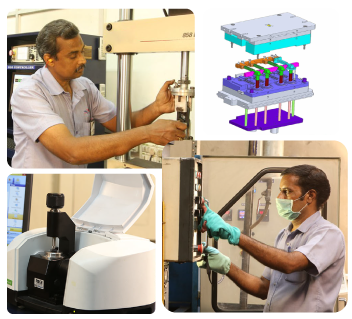

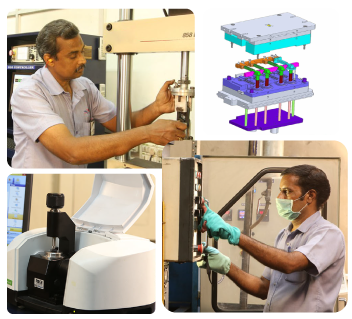

Manufacturing Practices and Certifications

The company’s rubber compounding facility boasts fully computerized

chemical weighing systems with Poka-Yoke in place,

ensuring precise measurements. Mixes are barcoded and stored in a

fully

air-conditioned vertical storage facility

utilizing a FIFO system. Additionally, pre-formers are employed for

crafting rubber slugs of accurate weight and shapes.

The facility is equipped to source steel, cast iron, and aluminum

parts,

with a dedicated tool room housing VMC, CNC

lathe, EDM, surface and cylindrical grinding, and pantograph

machines.

System certifications

- IATF 16949

- IRIS

- ISO 9001:2015

- ISO 45001:2018

- NABL Accredited lab

Special quality awards

- TPM from JIPM

- QI from Ford

- VDA 6.3 from Webco & ZF

- SQ Mark from Hyundai

- ASES from Renault Nissan

Vision and Values

Vision

To exceed customer expectation by Providing world class quality products and ensure prosperity to all the stakeholders through Trust, Value and Service.

Values

- Agility

- Innovation and Technology

- Customer Centricity

- Accountability & Ownership

Milestones

Expanding Reach and Unmatched Quality

1962

Tyre Repair Material

1962

Tyre Repair Material

1977

Inhouse Tool Room

1977

Inhouse Tool Room

1981

Injection Moulding

1981

Injection Moulding

1986

Engine

Mounts for

Maruti

1986

Engine

Mounts for

Maruti

1996

Tie-up with Bridgestone

1996

Tie-up with Bridgestone

1998

ISO 9001 Certification

1998

ISO 9001 Certification

1999

QS 9000

1999

QS 9000

2004

TPM Excellence & TS16949

2004

TPM Excellence & TS16949

2006

Supply to Nissan

2006

Supply to Nissan

2007-08

ISO 14001 Certification

2007-08

ISO 14001 Certification

2013

Ford MMOG & VOA 6.3

2013

Ford MMOG & VOA 6.3

2014

Ford QI Award

2014

Ford QI Award

2016

TQM

2016

TQM

2017

CAT SQEP Award

2017

CAT SQEP Award

2018

IAFT & NABL

2018

IAFT & NABL

2020

IRIS Certification (for railways)

2020

IRIS Certification (for railways)

2021

Caterpillar Best Quality Performance Award

2021

Caterpillar Best Quality Performance Award